Here are the new models that are now being offered. There is still time to order the original project’s F62/F77 keyboards, but they are on a “while supplies last” basis.

Currently in stock: All F62 and F77, Ultra Compact F104, Ultra Compact FSSK, F15 Split Ergonomic, F50 macro pad, and the Split Ortholinear keyboard (one left of this model – email me if interested)

Currently in production: The 3 metal case classic Model M style F104, FSSK, and F122 keyboards and the Round 2 classic style Beam Spring keyboards

You may see that updates are only once every couple months on the blog (this post was late! My apologies for the delay), which summarize the frequent updates posted on the Deskthority and geekhack forums, so please head over there for the updates as they happen.

Currently the order backlog for in stock items is down to about one month, as it has been for the past few months. Just about everything is in stock, outside of the Round 2 stuff, pad printed keys, and new keycap designs.

As a reminder I definitely recommend ordering the Low / Custom Serial/Production Date “Skip the Line” option to wait the shortest possible amount of time. To upgrade an existing order, please order this store item and choose free/other shipping at checkout, immediately before clicking Place Order. This will also be a great way of supporting the project a little extra to help cover the tens of thousands of dollars in project cost overruns.

Linus Tech Tips

It is a great honor for the New Model F to have been shown in the Linus Tech Tips tech upgrade video posted today!

Alex from LTT had the Brand New Ultra Compact F104 keyboard custom finished at an automotive paint shop and the result looks nice! It is great to see folks customizing their Model F keyboards!

Direct link to the keyboard portion of the video: https://youtu.be/b5hZVDoifHo?si=BCAgG5l1mYC9Out2&t=1200

The Model F has made it to the PC World Best Mechanical Keyboards of 2023 list! A nice honor for the project.

https://www.pcworld.com/article/1966306/best-mechanical-keyboards.html

Recently a great review of the new Model F keyboard (Ultra Compact F77 variation) was posted on EuroGamer

Featured in Hypebeast and JJJJound

A design studio and retailer company, JJJJound, purchased some F62 keyboards with a custom keycap design with the intention of reselling. They posted the product today on their blog and everything sold out within one day. (n.b., I still have stock of F62 and F77!).

https://hypebeast.com/2023/12/jjjjound-vintage-mechanical-keyboard

https://www.jjjjound.com/en-jp/blogs/projects/jjjjound-mechanical-keyboard

I have been in talks with other companies to resell / distribute the new Model F keyboards (for example, to have some inventory stock in Europe for faster shipping) but so far no one else has taken this on. Let me know if you are interested in this or can help in any way.

Having shipped more than 4,900 boards, there are quite a few reviews and postings. I have compiled dozens and dozens of reviews and postings on the Model F and beam spring keyboards here: https://www.modelfkeyboards.com/press/

Final sale on the out of production keyboards (F62 / F77 / Round 1 F104 FSSK B104 and BSSK)

Currently the keyboards are discounted about 50% or more and some now sell for less than $200. If you have been holding off joining the project due to lack of funds or because these boards were not affordable now is the time to get a new Model F or beam spring! A lot of folks who have a new Model F are picking up a spare to use at another computer or to keep for future usage.

After 8 years (doesn’t time fly! Does 2015 seem a long time ago to everyone here?) these earlier projects are finally winding down. Now is the last chance to get these keyboards. Currently all variations are in stock and expected to ship within 1-4 weeks as I move through the backlog.

Once most of the stock sells out over the coming months, pricing is expected to go back up for those who want any of the final remaining boards. So far more than 4,900 Brand New Model F and Beam Spring keyboards have shipped, with many more in the queue as we wait for the factory to wrap up production.

I also have a number of factory soldered controllers+ribbon cables+capacitive PCBs for the F62 and F77 models. If you are looking to upgrade your keyboard to have the latest USB-C controller or if you want to pick up a drop-in spare replacement please feel free to order the controller plus 30 units of the store item $1 increments which includes the PCB and factory labor costs.

Production Status – when are my orders arriving!

The Round 2 Model F and Beam Spring boards should be wrapping up production and assembly over the next few months and arriving to me around mid-year, a delay from the original expectation of being completed around this current time. All these Round 2 boards should be going out at the same time once they arrive on the container ship, so if someone decides to order an additional board and they have two boards on order then they usually get to skip the additional line and have both boards go out in the same shipment and at the same point in line as their first board.

After assembly and packing is completed, we then have 6-8 weeks for the container shipment and arranging local delivery to me. As I always say, we are at the mercy of the factories for their production timeframes. This low volume project is far from the highest priority but I am thankful that the project can exist without economies of scale.

The factories all understand that the quality control is very important for all these parts so we prefer that they get things right even if it delays things.

A few folks have asked me to switch them to in-stock round 1 boards, such as the ultra compact F104, ultra compact FSSK, ultra compact B104, and ultra compact BSSK, if they prefer not to wait. If interested, please email me as I still have some of these boards left but stock is low and they will not be made again.

Model F specific production status details

Round 2 Model F classic style cases: They made the batch of black cases but we still need to finish the other cases and finish assembly. The factory needs to confirm the finalized case colors and texture before powdercoating can start.

Inner assembly (all F104 and FSSK inner assemblies have been produced and assembled, including the barrels, flippers, PCB, inner foam, and clear mylar sheet).

F122: the F122 sample inner assembly still needs to be approved before F122 TIA and BIA production can start. I am currently evaluating the latest F122 keyboard. So far I see no errors with the inner assemblies.

Keycaps: in preparation for the new boards, I ordered several thousand extra key sets and miscellaneous extra keys which were all completed and are currently on hand, so we do not need to wait for keycap production for the new Model F keyboard designs.

Boxes: the new folding style boxes have been approved for production for all Model F and beam spring boards; the artwork remains the same as before. More details on these boxes are below.

Outside protective foam: has been approved for production. These will be end cap pieces similar to those of the latest classic style F77.

While this does not hold up any Model F production, unfortunately there were production issues with the small batch of new keys for ISO Enter, Code, and PC AT Big Enter. The factory is working on remaking this batch (photos shown below). They will be available in pebble, ISSK Blue, black, and dark gray. As always everyone interested in reserving one of these keys (alone or as part of a set) please sign the Google Form: https://docs.google.com/forms/d/1vsamkl_jOqp6wAEfZGeivQZ8ZaibpoT0WQkDG39r08Q/

If anyone prefers not to wait and wants to switch to a Round 1 Model F board please let me know by email as I still have some units remaining.

Beam spring production status details

The Round 2 boards still need to finish production and assembly, so I hope that they can arrive to me later this year, around mid-year. As mentioned before things have been delayed from the original hope that they be completed earlier. Like with the Brand New Model F Keyboards project, no one aspect has bottlenecked the project and caused the delay but a number of aspects have taken longer than expected. The factory has their new year break for the next few weeks so things will continue after then.

Same as with the Model F noted above: If anyone prefers not to wait and wants to switch to a Round 1 beam spring board please let me know by email as I still have some units remaining.

Beam modules parts A and B:

Recently completed, but there was an error with part B discovered just before the new year break for the factories, so these parts need to be remade. These took over one year to produce, much longer than expected. Over a hundred thousand parts of each type were produced.

Beam module part B’s (the white part’s) assembly with its metal part has been improved for a nicer looking rounded assembly finish on the nub that is below the metal part. The factory has made thousands of these as part of the updated beam modules (all the ones with the press fit washers on top) and they are nice.

Metal parts for the modules:

The new modules from this February batch now sound great and were just approved for production yesterday, so we are just waiting on part B to be remade. A month earlier I noted this: The new modules using the older metal part for beam flipper sound great and are very close to the IBM originals. The tooling for the metal part for the beam flipper was updated last year but the updated tooling designed to get things even closer needs some work to get the modules as good sounding as possible.

The updated press fit washer mold for the beam modules:

Has been completed and approved, and I believe the factory has finished production of these parts if I remember correctly. This is an update over the original glued metal washer design; it allows for quick and toolless disassembly and repair of the beam modules.

Cases:

All but the beige and industrial gray case colors were approved (I want the colors to be even more accurate to the IBM originals so I rejected those two samples). The paint texture finish is not yet finalized.

Capacitive and controller PCBs:

wcass and Rico have finished the PCBs for the various beam spring models and I ordered the updated samples a few days ago. Rico’s Leyden Jar Rev 3 controller is so far working flawlessly in my testing and these will be the default controllers for the B104 and B122 (plus the F122), though the controllers will hopefully have firmware for all the various Model F and Beam Spring models in the future. As mentioned before, after the ATMEGA32’s run out I expect everything to have the Leyden Jar as the factory-installed controller.

Keys:

The PBT double shot keys and wcass xwhatsit controllers were completed last year.

Boxes:

The box designs have been finalized. The art will be just about the same as the Round 1 boxes shown on the project web site, but the boxes themselves will switch to a tab locking foldable design similar to the boxes IBM used for the original IBM Model F XT and AT keyboards (more details below). I have approved the box designs for production.

The outside protective foam:

Will be similar to the end cap style used on the final production round classic F77 Model F keyboards; after the keyboard samples are approved then they can make the cutting tool for this foam.

Inner foam:

The inner foam that goes between the tops of the modules and the top inner assembly will be evaluated with the forthcoming samples.

Working sample status:

The factory still needs to produce fully working samples of each beam spring keyboard model for my approval, and then mass production and assembly of the remaining case parts can start. The tooling for these cases took months longer than expected to complete. The sample cases and their TIA/BIA’s are completed and are now waiting to be powdercoated and assembled.

Major project milestone

The project has passed $3 million in orders! It is great to know there has been so much interest in the old beam spring and Model F keyboards.

Beam spring cases detailed production update

The factory has needed extra time to perfect the tooling for the cases and expects to finish up with the samples of each keyboard model in March (they already finished making the samples of each keyboard’s case, bottom inner assembly, and top inner assembly so we are just waiting up on the plating and powdercoating finishes to be completed). Here is an interesting video showing how the factory makes the curve on each beam spring case. The video shows them testing the curve on some test metal instead of what would be the final case.

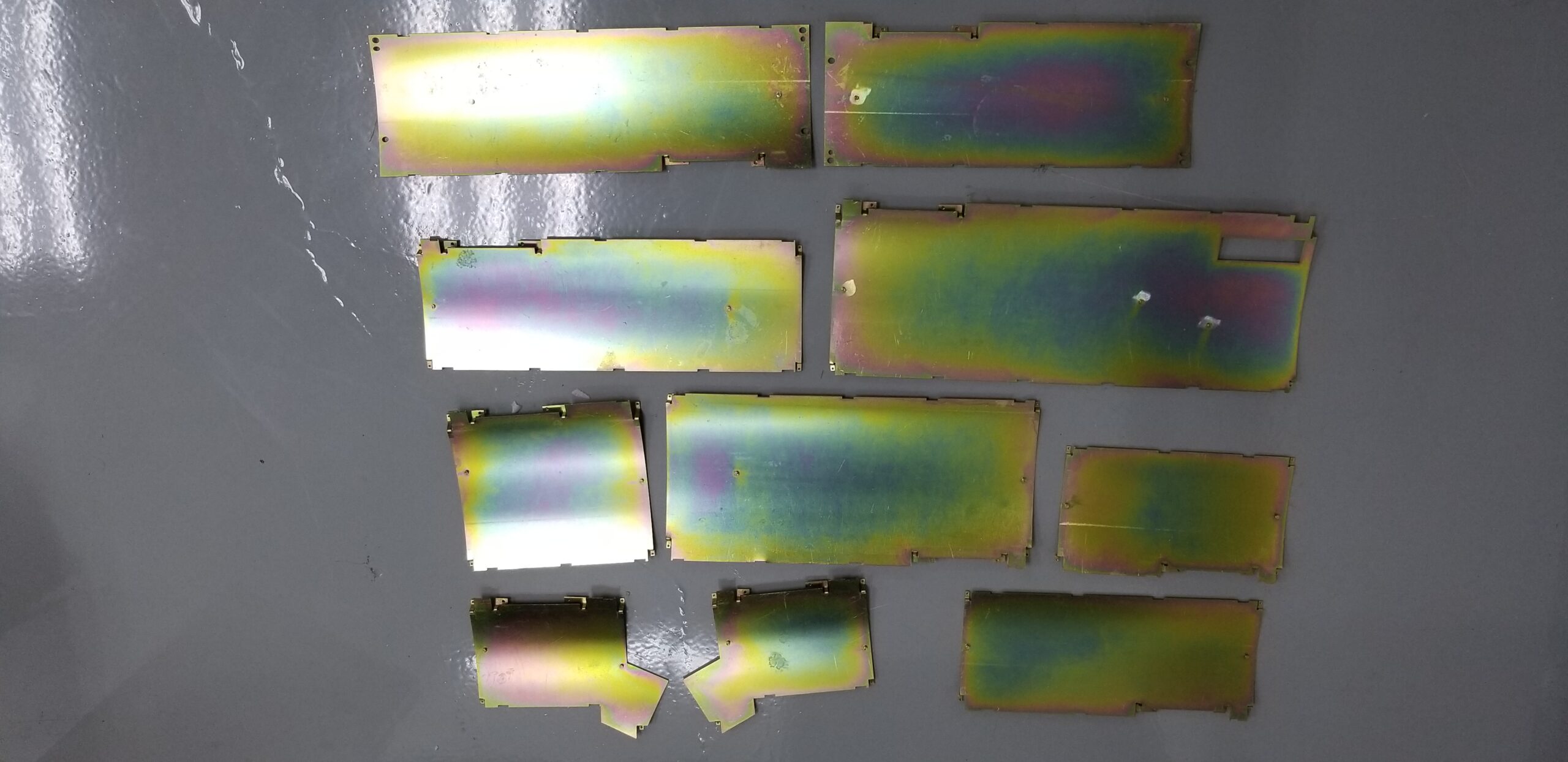

Here are some photos of the uncoated aluminum beam case prototypes from the new tooling. They are made from a flat piece of aluminum cut and folded/bent into shape. The samples show the cases without the finishing operations which is why things don’t line up 100% as with a finished product.

New BSSK layout with split backspace and right shift

Thanks to Fond Lion, there is a new layout option available for Round 2. Previously only the B62 offered a split right shift with the option of a split backspace. This option is only for the BSSK – please contact me to arrange paying for the additional tooling costs for the F104 for example.

You can upgrade an existing order or order a new keyboard with this layout.

Just like with the other custom tooling project (cut out full 5×3 right side block), the tooling was paid for in advance and folks will pay the person directly to take part in it. This modification is ANSI only, ISO is not available with this mod.

To upgrade, please order the BSSK with ANSI layout on the project web site (or reference a previous BSSK order if applicable) and then PM Fond Lion directly to arrange payment to Fond Lion. After payment is completed and I am notified by Fond Lion, I will upgrade your order. The price for the upgrade is $200 (or $100 for people who can’t afford it otherwise). If you are not a Deskthority member feel free to email me and I will pass along your information to Fond Lion over email.

https://www.modelfkeyboards.com/product/beam-spring-keyboard/

December Meetup

Nice seeing everyone at the NYC mechanical keyboard meetup! There was a great turnout and a good amount of enthusiasm for the old style keyboards. Always nice to put the faces to the user names of some GH, reddit, and DT forum members. I brought the Round 2 B104, Round 2 F104, Round 1 Beam 104, and Classic Case F77 to the meetup where folks got to try them out and compare them with other keyboards the people brought.

Two Model F history resources: the original development of the Model F and IBM 4700 development

First article:

The inventor of the Model F keyboard, Dick Harris, has written an article and shared some videos about the development of the “Keyboard F” as it was initially known:

https://deskthority.net/viewtopic.php?f=2&t=28325

A big thanks to Deskthority forum member SneakyRobb for sharing this.

Second article:

Here is a great original IBM 4700 system guide book linked to by sharktastica on another thread:

https://deskthority.net/viewtopic.php?p=517054#p517054

It includes some photos and expected specifications of the keyboards.

Deskthority forum member thefarside created a helpful post (linked above) showing the highlights from the above-linked PDF. It is interesting to see how different the F77 final weight ended up being (7.5 pounds for IBM’s F77 compared to the 4.4 pound estimate!). The XT style layout in that photo appears to be a non-functioning mockup? There appears to be no room below the keys for them to be pressed down, most noticeably for the Enter key.

Pad print update

The corrected pad printing jig was completed in mid-November and the factory then was able to move to the next step to further adjust the custom-made pad printing machine for this pad printing. The process has taken far longer than expected. The first jig had some errors and had to be redesigned.

This month I will be submitting the artwork to the factory for the first testing with production artwork, which is expected to be the same as the art used for the sublimated keys.

As always please do sign the interest form to reserve your pad printed set. https://docs.google.com/forms/d/1873Q9wJFyNvJ4-TEBN6P9JbzaVxErbNd-h4XtN1DfNk

We are still not decided on UV coating vs uncoated for the pad printing. I think the uncoated looks nicer and closer to the IBM originals but the UV coating may add some extra longevity to the keys which of course wear down with usage.

New additional keys production photos (the status update is above in the production status section)

Can you really tell how good these keyboards are from pressing a key a few times or using a switch tester?

For a Model F switch tester, some folks think they will just order the keycap (Extra Keys product page), barrel, and flipper with spring. Or they will just buy a beam module to test out the new beam spring keyboards.

To be honest, trying one switch is not a good way of deciding whether you like the Model F or Beam Spring keyboard. What I recommend is to buy the lowest cost Model F or beam spring keyboard in the shop and see if you like it. If not, you can always sell it on reddit mechmarket or eBay. It would probably cost you, net, the same either way.

Clicking one switch doesn’t convey the overall accuracy, comfort, and typing experience of using a Model F or beam spring keyboard for extended typing sessions. These keyboards prove themselves through long typing sessions, where the components interact with the big metal plates to make the best typing experience with solidly built components making up a keyboard that folks have used for decades, instead of most keyboards which weigh 80% less, are mostly plastic, and use pad printed legends (instead of dye sublimated or double shot legends on the F and beam spring boards, respectively); these cost-based compromises make them not destined to last more than several years of intense usage. You can’t really tell how good these IBM-designed keyboard technologies are from pressing one switch a few times outside of the keyboard. Reminds me of the Pepsi Challenge from many years ago. If I remember correctly, when an academic study was done to evaluate the veracity of this challenge, most folks preferred a sip of Pepsi but overwhelmingly preferred Coke once they drank the full contents of each can.

To quote one user comparing Model F and Model M keyboards:

“My opinion echoes others: the M is a fantastic keyboard, but the F is noticeably better. The technical differences between the switches are minor on paper, but they become amplified when you adapt a light typing style, and compound further if you have to type a lot.

The light typing style is the key here: if you’re a heavy typist, there’s almost no difference between an F and M. When you type lightly, the small details in the design start to creep up. Both keyboards allow for light typing due to how buckling springs work in general, but the lighter keystroke that the F’s capacitive switch uses, combined with the ever-so-slightly more accurate “snappier” feeling actuation, add up to a more accurate feeling, less fatiguing board overall.

These are differences you feel a little bit moment-to moment, but a lot more after extended typing sessions. If you’re typing a one page essay, this may not be noticeable at all. If you’re typing 20 pages of documentation or coding all day, 5 days a week, the M becomes noticeably more fatiguing and less accurate than the F. Not a bad board, I must emphasize, just noticeably not as good as the original!

The F is closer to perfection. It’s not a great value like the M, and the differences between the two boards are ultimately not mind blowing, but sometimes it’s worth reaching for that next level up in design perfection.

Especially if you type as much as I do.”

And here is a quote from someone comparing the beam spring to the Model F and prefers the beam spring (though I would say most folks should start with the Model F before moving to the beam spring):

“Key feel:

I’m not great at reviewing switches but my first thought [about the beam spring] was “Wow!”, this is the type of feeling I was hoping for when I purchased the Model F77. The Model F is still great, but I can see why others consider this a “step up”. Each key feels distinct and “heavy”(?). It does feel like you’re typing on a typewriter. I think it will take a few days to get up to speed with it, I’m not as fast as I was with the Model F, but this definitely feels more “fun” to type on if that makes sense at all.

I also enjoy the sound a lot more than the sound from the F77. It’s louder I think but it doesn’t have a “ping” sound that the F77 had.”

Firmware updates

The latest firmware, NathanA’s Vial:

I have just updated the zip file in the manual on the project web site with all of the NathanA firmware files. This one zip file includes all of the NathanA vial files, the old QMK files, the source code and build files, and the pandrew utility for Windows and Mac.

The batch files have been renamed and reorganized to replace abbreviations with language that more closely matches that of the project web site keyboard configuration. Once again a major thanks to NathanA for this enormous undertaking.

As always please do review the manual for instructions before doing any firmware flashing or you’ll likely run into errors.

Please do share feedback here after testing this firmware!

https://www.modelfkeyboards.com/wp-content/uploads/2020/07/QMK-layout-files.zip

Leyden Jar:

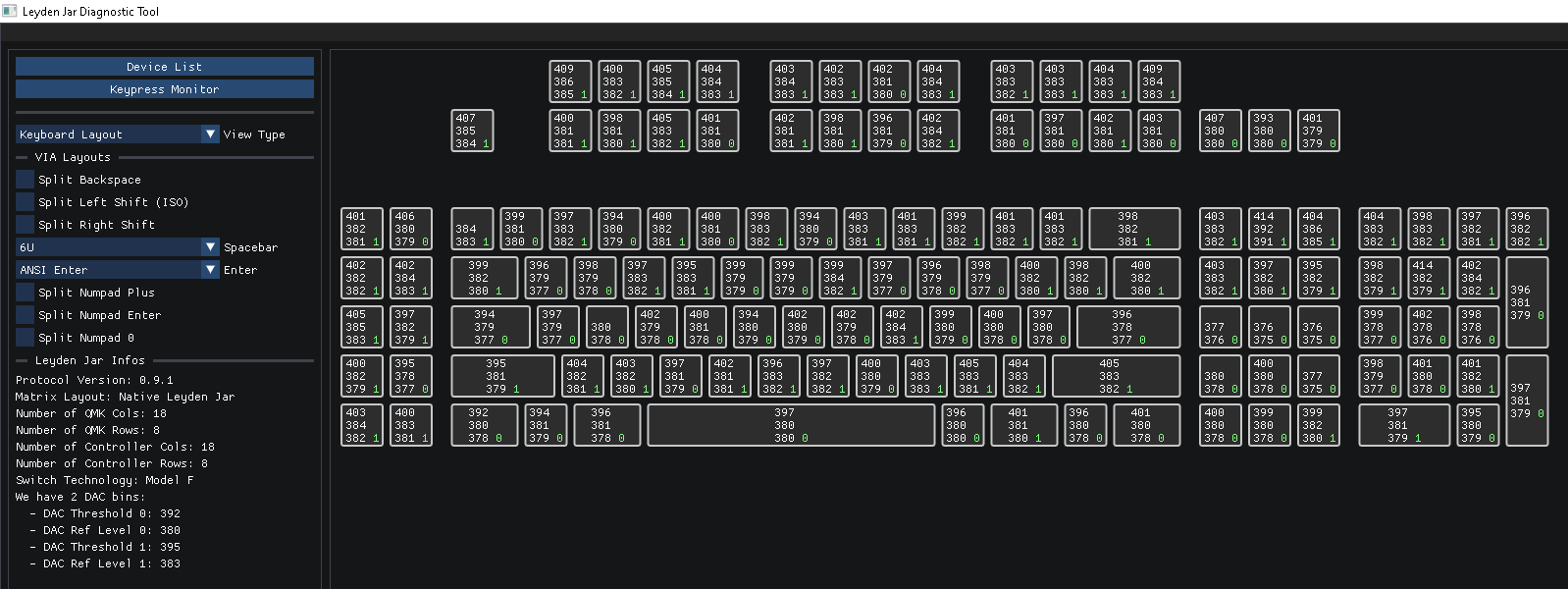

Back in mid-October, Rico released the latest Leyden Jar beta firmware (links below to the firmware and to the PCB). I have tested the firmware with the F122 prototype and the controller is working perfectly. As a reminder this controller has the extra 2 columns needed for the F122 and B122.

There was an issue with two keys giving some trouble (the Home key has a higher resting number of 392 compared to ~380 for most others) but it seems to have been resolved after adding in a second bin, replacing the spring, and reseating the key. The firmware has an adjustable bin count (factory default is tentatively set to 2 bins given the unpressed voltage variations). The bins separate the keys into groups based on their unpressed numbers. The downside to more bins is a reduced scanning rate (though I don’t think it can be noticed in practice!).

https://github.com/mymakercorner/vial-qmk/tree/leyden_jar

https://github.com/mymakercorner/Leyden_Jar

There is also a terrific new utility that Rico has created (screenshot below) that allows signal level monitoring, entering the bootloader, and monitoring keypresses, among other functions and informational displays. Not shown in the screenshot is the device list and its menu with the signal level monitor, keypress monitor, and enter bootloader buttons, which appear when you click the Device List button. The utility is not yet ready to be shared.

A discussion on the QMK approval process:

Thanks wolfman for the QMK update. It is interesting to see a behind the scenes look at the approval process. https://deskthority.net/viewtopic.php?p=517900#p517900

Modding the split Model F keyboard firmware for additional function layers

Here we have five posts from Deskthority forum member sensy, the last of which links to a sound test of the Model F Split Ortho limited run board (I have one left from this run – email me if interested):

https://deskthority.net/viewtopic.php?f=50&t=11046&p=518139#p518139

https://deskthority.net/viewtopic.php?f=50&t=11046&p=518144#p518144

https://deskthority.net/viewtopic.php?f=50&t=11046&p=518149#p518149

https://deskthority.net/viewtopic.php?f=50&t=11046&p=518230#p518230

https://deskthority.net/viewtopic.php?f=50&t=11046&p=518255#p518255

New custom mods and customer images:

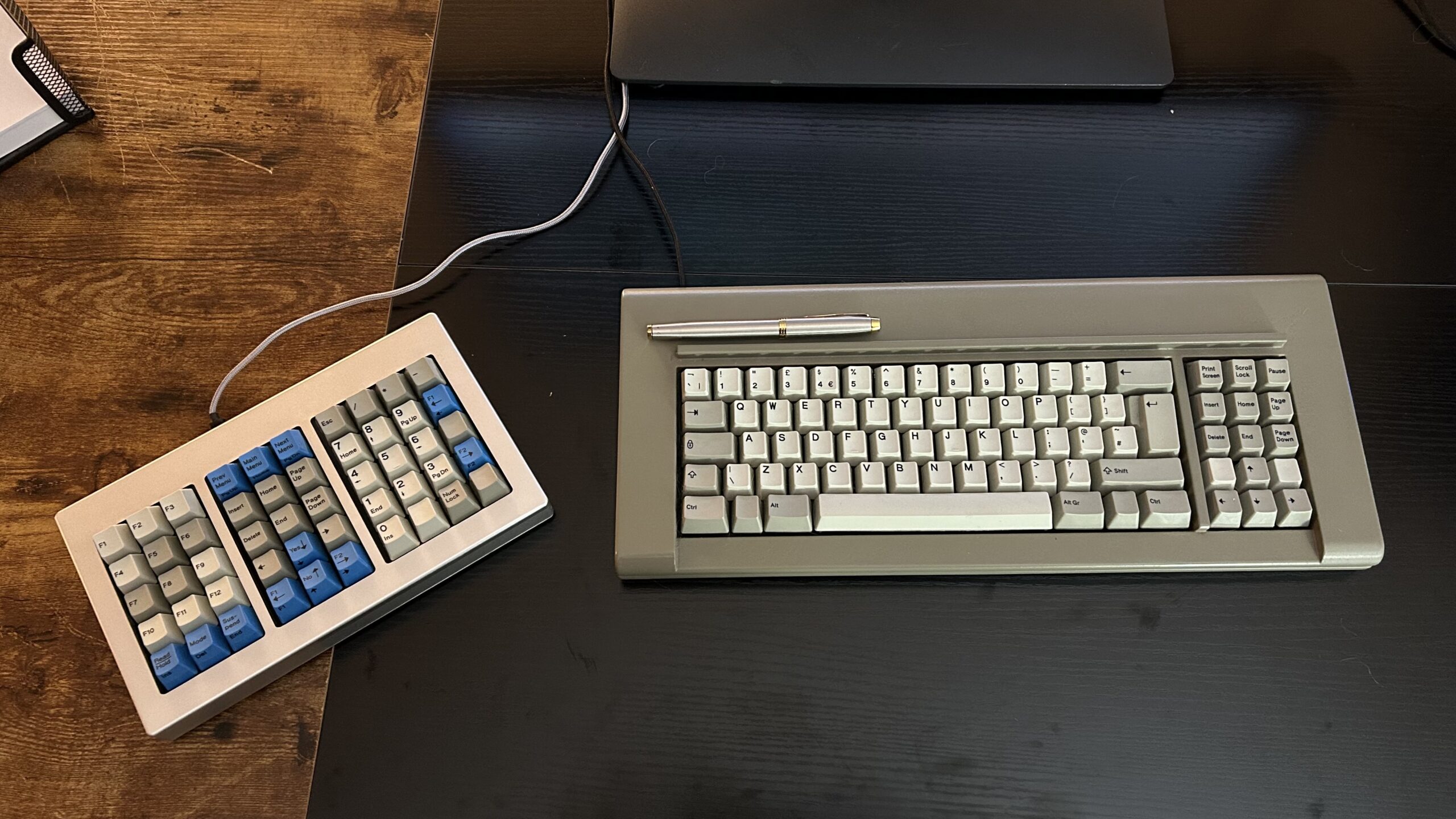

With permission I am sharing the first photos of a new Model F setup with the F50! The new project keyboards started going out this month but there are still many more to ship of each of the three types of keyboards.

Thanks to Deskthority forum member depletedvespene for sharing a custom layout. I like how much thought was have put into devising the optimal layout. https://deskthority.net/viewtopic.php?p=517134#p517134

Posting (with permission) a nice red F50 and off-white/beige F77 setup. “I use it with REWASD and plane black keys to give me more key options and macros per application.”

Sharing with permission another F50 customization. This one is interesting because some flippers were removed to allow for 2U vertical keys to be placed (one can’t just remove the spring as the stabilizer insert would not have enough room to be seated inside the barrel fully).

Also the number pad has some reversed parts compared to the IBM right-sided number pad block design. I don’t recall seeing such a mod before – is this common with left-handed number pad keyboards?

Deskthority forum member taraskremen had a good reply to the above question:

https://deskthority.net/viewtopic.php?p=517284#p517284

Posting (with permission) another nice setup: the compact F77 dark blue case with a customized key setup.

Deskthority forum members Arkku and AlexB555 posted some nice photos (linked below). The custom sets for Quebec CSA and French BÉPO turned out especially nicely with the multi-color legends.

https://deskthority.net/viewtopic.php?p=518035#p518035

https://deskthority.net/viewtopic.php?p=518054#p518054

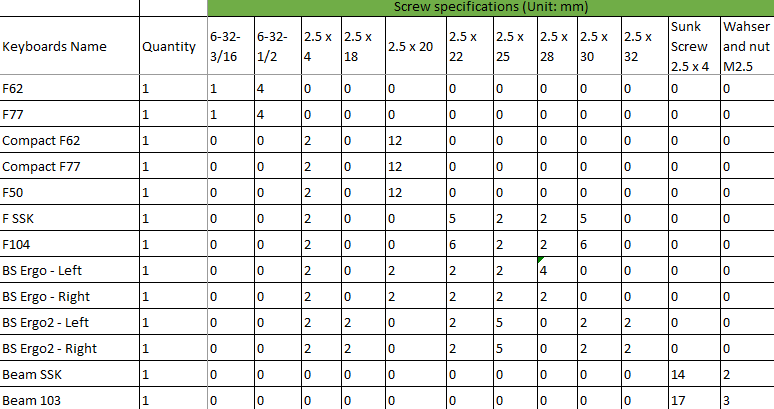

Screw specifications and spare screws available

If anyone needs spare screws / bolts please let me know as I have plenty of them. The zinc case boards use 6-32 x 1/2″ thread screws with philips heads. Some of the total screws in each set may have the wrong quantity number so please double check.

As noted earlier the project’s T8 M2.5 metric screws were custom molded for this project with various lengths, so they cannot be found elsewhere. Below are the metric screw lengths for everyone’s reference. Please email me if you need additional sets of screws.

Controller ground screws for all keyboards (2 per keyboard) are 6-32 x 3/16″ (keyboards with P clips use these same screws).

The Round 2 keyboards use different screws, primarily those with hex heads or torx heads, specifications to follow later.

Update on the boxes

For the next batch of keyboards (M Style Model F and Beam Spring Round 2) I am considering the tab lock style boxes, which are more authentic to the original IBM Model F retail boxes. Same artwork as the other style, standard brown boxes – not the white and gray boxes of the originals.

Example: https://www.packagingprice.com/tab-locking-mailers.html

From my collection: https://flickr.com/photos/modelfkeyboards/51941436172/in/dateposted-public/

https://live.staticflickr.com/65535/51941436172_4ac726793b_h.jpg

https://www.flickr.com/photos/modelfkeyboards/

On the subject of relegendables

I have not seen too many photos of custom-printed relegendable keys in use on the Model F keyboards – everyone please do share some photos and descriptions of these keys! Are they primarily for application-specific options or more for flexibility to change up the keys every now and then without ordering preprinted keys?

On the subject of dust

I am curious, for those who have been using the round 1 beam spring boards for at least a number of months, is there any feedback on the effect of dust intrusion on the sensing? Has anyone benefitted from opening up the board and cleaning it up, or is dust not much of an issue?

A discussion on the project’s philosophy, “buy it for life” and a repair mindset, along with pricing of repair parts

You can definitely recommend a Model F to friends and family members even though it requires maintenance to keep it running, hopefully for many more years. Paying for the parts alone as part of the first aid repair kit or separately is far less costly than paying a repair shop for parts and labor or discarding the product entirely when one part breaks. These keyboards are fully repairable and can be fully disassembled with just screwdrivers and pliers, unlike many other keyboards. The main philosophy of the project is to encourage users to learn how to take control of the repairs and maintenance of their keyboards, one benefit of which is to allow the keyboards to be priced as low as possible and to avoid the need for repair and phone staff.

The pricing is quite reasonable for all extras and has even gone down for some extras like the keys and key sets. Everyone gets the fully discounted price for all items regardless of quantity ordered, except for the transparent relegendable keys which have quantity discounts. Some folks may not fully realize that the price of any custom-made item is not based on the material cost or the variable production cost – one needs to allocate the overhead costs. Comparing it to a mass produced item like an MX style switch which is probably made in the tens (or hundreds?) of millions each year misses the important detail that this project does not have the economies of scale of such an item. With a small-scale project like this one you are also paying more to allocate all of the additional project costs on a (lower quantity) per-unit basis: quality control and assembly costs, tooling and mold costs, express/air mail shipping costs, sample/prototype costs, project cost overruns, other fixed costs, and so forth.

And now for something completely different, to close off this update post

A production photo I recently came across of the various bottom inner assemblies for all but the Round 2 Model F boards.