As a reminder here are the new models that are now being offered. There is still time to order the original project’s F62/F77 keyboards but they are on a “while supplies last” basis.

Currently in stock: All F62 and F77, Ultra Compact F104, Ultra Compact FSSK, F15 Split Ergonomic, F50 macro pad, and the Split Ortholinear keyboard

Currently in production: The 3 metal case classic Model M style F104, FSSK, and F122 keyboards and the Round 2 Beam Spring keyboards

With the launch of these new models the combined F and Beam projects now total $2.9 million in orders!

Major price discounts to close out the older projects which are now end of production

All F62 and F77 models, plus the compact F104 and compact FSSK keyboards, are now end of production and the remaining units are being sold off at a significant discount, while supplies last. Currently all variations are still in stock. Click the Shop button at the top of the page for details and pricing.

Pricing on some of the newer models has also changed so please do check out the latest updated product pages to see which models you would like. Some keyboards that you were looking at before may be more affordable now.

I strongly recommend ordering things now while the current pricing stands and current stock remains, whether to pick up an additional / backup keyboard while you can still buy one new, joining the project for the first time if financial limitations due to the higher pricing were holding you back before, or to pick up an additional keyboard, first aid kit for future repairs/maintenance, a spare key set to use when your current one’s top textured surface wears down over time with usage, spare custom made USB cable, transparent relegendable keys, etc.

Model F Split Ortho, F15 Split Ergonomic, and F50 keyboards closeout

A reverse/Dutch auction was conducted this year to fairly allocate the limited number of these keyboards that were produced. In summary, you would bid the amount that you were able to pay for one or more keyboards and the Nth lowest bid was the price that everyone paid. Currently nearly every keyboard has been reserved and paid for, but there are a very small number of boards remaining. I expect to mail these out later this month.

The project is now open to the public, so you can head over to the shop page to customize your custom Model F but please note that once these sell out, you will not be able to order one. No need for bidding or reserving anything.

Project featured on Linus Tech Tips ShortCircuit

It was a great honor for the new Model F project to be featured on the Linus Tech Tips ShortCircuit YouTube channel!

If anyone can reach out to the various YouTube channels and reviewers on their social media it would be much appreciated. This would help get the word out about the new project. It’s likely that many of the reviewers became aware of the project through these contacts.

By the way, if any marketers reading this post have any advice on advertising/marketing please do email me how you think the word can get out more and the project can expand even more – I think a lot of folks would be interested in the F and beam spring projects if they were aware of them. So far I have not done any marketing campaigns but I am interested. And general advice is always appreciated, whether on the forums or directly through email.

Can you believe over 100,000 views for the Model F Keyboard ShortCircuit video? Who would have thought there was so much interest in the Model F! It is great to see.

My reply posted in the YouTube comments is below, since it may be tough to find among the many comments:

“Hello, project coordinator here. Thanks Nicholas and the entire ShortCircuit team for putting together a nice video covering the Brand New Model F Keyboard! It is great to get the word out about these great keyboards that definitely take some getting used to!

Kindly see my replies to some of the notes brought up in the video:

The pinginess / reverberation: Some folks that prefer a Model F board without the higher pitch sounds. The best thing about buckling spring keyboards is the a longstanding community that has come up with various repair and maintenance step by step guides and mods, including the Floss Mod and the grease mod, to reduce or eliminate the high-pitch / pinginess while typing. My guess is that the main reason for the pinginess is the super thick steel plates reverberating inside the keyboard.

Why True Red? Well it’s the Pantone designation for the particular shade of red. The factory prefers Pantone references when doing the finishing.

Recessed keys: The reason for the extra recessed keys for a couple of the rows is that the Ultra Compact F104 case top in the video is flat and the Model F and Model M design require a curved plate inside the keyboard. One result of this is that the key profiles are all uniform and a key can be installed on the various rows. The Model M style F104, FSSK, and F122 cases are all curved where the keys are, just like the IBM originals, so the keys will stick out more evenly.

Casting: The Ultra Compact cases for the F104 and FSSK were CNC milled and have 3 main parts, while the ultra compact cases for the F62 and F77 keyboards are die cast, while the first rounds of the compact F62/F77 boards were CNC milled. The Model M style case Model F keyboards all have die cast cases.

Regarding the low serials, they are mainly there to allow folks to offer a little extra support to help cover the tens of thousands of dollars in project cost overruns, the near-endless express air mail sample charges over the years, etc. Many folks also like a custom serial because it allows them to pick a date for the production date, like their birthday or an anniversary of some date. In the Model M community forums it is always notable to get a board made the same year you were born, or if you were lucky, on your actual birthday (and actual birth year too!).”

Model M vs. Model F Keyboards — What is the real difference?

Due to the significant feedback I received after the video launch with folks not knowing much about the differences between Model M and Model F keyboards I made a quick video, which is now also on the project home page as a video and a slide deck.

Production status for the various projects

For the most frequent day-to-day updates on the various keyboard projects please head over to the mechanical keyboard forums such as Deskthority and geekhack (links can be found above by going to About, Forums/Press). I only post on the blog and send out email newsletters on a more limited basis, to summarize what has been going on.

As I always say, we are at the mercy of the factories for such low volume production, especially around the timeline. It is truly a miracle and a great sign of today’s manufacturing advances that such complicated projects to bring back these great old style keyboards can proceed today given the limited economies of scale and even though production volume is significantly limited compared to most mass market products and we are far from top priority clients for that reason.

Here is the status by keyboard type:

Classic Case F104 and FSSK: inner assemblies are complete, first batch of cases is 900 complete, still need to complete the balance of the cases (see below for additional details).

F122: some errors with the prototype inner assembly plates; I have ordered a new sample of the top and bottom inner assembly plates. I assembled the F122 prototype with Rico’s latest Leyden Jar controller that just arrived recently and noticed some things that I want to change regarding the inner assembly tabs and posts and their alignment with the PCB so I will be requesting another sample of the top and bottom inner assembly plates.

Beam Spring Round 2: The factory is working on the new case tooling. I am working on finishing up a prototype of the Round 2 keyboard with the final production case design and new modules (the Round 2 keyboard had a working prototype a while back, just with an older case design and modules that were changed to be about 1mm taller to allow for the newly introduced top layer of inner foam above the key modules but below the top inner assembly, just like with the IBM beam spring originals). Two of the plastic module parts are currently in mass production (the beam barrel part A and B). The beam flippers finished production some time ago. The two metal parts will be entering production soon (they are retooling the metal part for beam flipper).

Here is a photo showing the assembly process of the second Round 2 B104 sample. The inner assembly is attached upside down to the bottom case so that it does not slip out of place. One can see that the flipper factory improved the color of the flippers – they are more of a deep black color compared to the dark gray color of the originals. There is no functional difference and no one can see this inside of the keyboard, but the black color is closer to the IBM originals.

The factory is still looking to wrap things up around year end, which means that the keyboards should start going out early next year. Please keep reading for more details on each of the parts.

Status on new keycap molds (non-stepped ISO Enter, Code key, and PC AT big enter) and new sublimated keys

The molds have been completed for these and the new caps are currently in production. I have a few unprinted caps in stock in case anyone is interested. Orders will open up as soon as the new sublimation jig is completed and tested working. Please sign the interest form here to reserve one of these keys or key sets: https://docs.google.com/forms/d/1vsamkl_jOqp6wAEfZGeivQZ8ZaibpoT0WQkDG39r08Q/

Also we have new 1.5U size sublimated keys added to the order list today, as someone just custom requested them. Feel free to order on the extra keys page if you are interested. All keys except 1.75U keys are now $3 each, down from $4 each. Available in pebble, blue, and dark gray. They should go out later this year.

Drop-in replacement PCB assemblies now available for F62, F77, compact F104, and compact FSSK

I have a bunch of presoldered controller+ribbon cable+large capacitive PCBs that can serve as drop-in replacements for these keyboards in case they are needed. Anyone who needs one or wants a spare please email me for details. It is always good to have a spare that you don’t have to mess around with desoldering and resoldering.

The next NYC Mechanical Keyboard meetup

It has just been announced and you can now get tickets. They usually sell out quickly so I recommend getting one soon. I just ordered my ticket and will see everyone there!

https://www.eventbrite.com/e/nyc-mechanical-keyboard-meetup-december-2023-tickets-727184567617

Major firmware announcement: moving to the Vial-based firmware

I am now expecting to base the project firmware off of the latest NathanA updates to the pandrew QMK firmware, which allow the use of the pandrew utility and its signal level monitor, Vial, and the online version of the vial configuration tool. This tool is great – I was able to connect the keyboard running NathanA’s updated firmware to the web site vial.rocks to reconfigure the keyboard without having to download anything or flash any firmware. Both the vial program and the vial web site both recognize any keyboard because they read the layout from the keyboard firmware – no need to load a json file or pick your keyboard and controller from a dropdown menu. So much easier. Are there any options on the QMK configurator that are missing from Vial?

In addition, I can report that the NathanA updated firmware (made from the same version of QMK that pandrew uses) is more stable than the firmware I generated from a later version of QMK, but still made before the big QMK updates. The latter one had some issues with repeated and missing keys, even after I removed and retightened both ground screws and removed and replaced two springs from frequently-transposed/switched keys. I also tested the Arkku calibration setup in the NathanA firmware and that also worked well.

Currently the firmware works without any issues on the round 2 FSSK/F104 boards. Again a big thanks to NathanA!

The first F104 and FSSK boards with the NathanA Vial firmware shipped last week! These will be the default going forward for more and more of the keyboard models.

Some more good news: NathanA’s workaround to allow layer sharing between both halves of the split keyboards is working; this functionality is built into the new firmware. I tested it on the production split boards and it is working.

There are some limitations as detailed in earlier posts from NathanA, especially this one: https://deskthority.net/viewtopic.php?p=516636#p516636

Layer programming would be normal with this and the base Vial firmware is already preprogrammed for the second layer. This NathanA firmware will be the one that ships with each board. The layers are programmed to each board and no additional hardware is needed, so this should meet most folks’ requirements. Instead of flashing the specific layout you want, there is one firmware for each type of keyboard. You flash that firmware and then can configure the board for split backspace, split right shift, etc. There is expected to be future support to flash the exact firmware you want from the start if you want to save a step (also good for the factory workers as they load these en masse).

These are not yet tested on the beam spring boards so it is just Model F to start with. Currently it is good on the F62, F77, and F104/FSSK Rounds 1 and 2.

Permalinks to the latest Windows and Mac utilities:

https://www.modelfkeyboards.com/wp-content/uploads/2020/06/pandrew-mac-utility.zip

Please note that the binary is not signed – you’ll need to “Open” manually in Finder. Please note that all files are provided AS IS, without warranty. Ctrl+click, then Open

Some features of the NathanA firmware:

Excellent stability in my testing

Vial support (after flashing this new firmware, you can just go to the web site vial.rocks to configure your board any time you want to change something, without needing to generate custom firmware and then reflash the firmware as with the QMK configurator web site. It works natively without needing a custom Vial program or web site or json file because the keyboard details are stored in the firmware and read by Vial). Vial even has a check mark to enable and disable NKRO right from the GUI.

Supports solenoids and LEDs

Supports pandrew’s diagnostic utility which has the Signal Level Monitor and Enter Bootloader features (you need to download the latest version which is found in the manual)

And many more features

There are two versions of the latest firmware (see the project thread’s recent Deskthority postings for the latest files):

The “allpads” version is the way that I prefer, with each pad configurable right away without having to click buttons to reveal pads in Vial. There is also a helpful bat file for each board (allpads version only). Once you enter the bootloader, you can run the bat file to automatically update the firmware and restart the keyboard, no need to unplug and re-plug the cable or use Atmel Flip!

The other file has the source code with a diff file that can be executed on linux to auto build all of the firmware files on your own, if you prefer it. To run NathanA’s bash script build.sh in Ubuntu, copy the folder newfxx-vial-package and all its files, then right click build.sh and select run as program.

This is what I do on a fresh Ubuntu install:

open Terminal program and enter one line at a time:

sudo apt update && sudo apt upgrade -y

sudo apt install python3-pip

sudo python3 -m pip install qmk

echo “PATH=$PATH:$HOME/.local/bin” >> ./.bashrc

sudo apt install git

qmk setup

The forthcoming Leyden Jar controllers also run Vial (see below for details).

Deskthority member wolfman is wrapping up the approval process for the refactoring to get the xwhatsit accepted into the main QMK project. Here are the details: https://github.com/qmk/qmk_firmware/pull/21193

Everyone feel free to test out this refactored firmware and let us know the feedback!

wolfman started with F62 for the refactoring submission, as they wanted only one keyboard at a time and count each variation separately, but the f77 should be able to be added if you download and modify the code: https://github.com/matthew-wolf-n4mtt/qmk_firmware/tree/model_f_labs/keyboards/model_f_labs

Model M style case production process

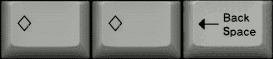

Three months ago I approved mass production of the Model M style cases. Due to some quality issues it took many months extra to get the quality to where it is now. The initial batch of 900 F122, F104, and FSSK keyboard cases (300 each style) has been completed and is being mailed to the assembly factory which will inspect the cases and then assemble them with the inner assemblies. The first batch just has black color cases, plus some uncoated cases of each type. The F104 and FSSK inner assemblies were completed a while back while the F122 inner assembly was not approved and a new sample has been ordered. Next up will be the batch of all remaining cases. The factory split things for quality control reasons, to make sure everything was being produced according to the requirements. They just need the latest firmware to be loaded and for them to be installed into the cases when they are done.

Die casting of the Model M style cases: Here is an interesting video from the factory showing a case as it is cast:

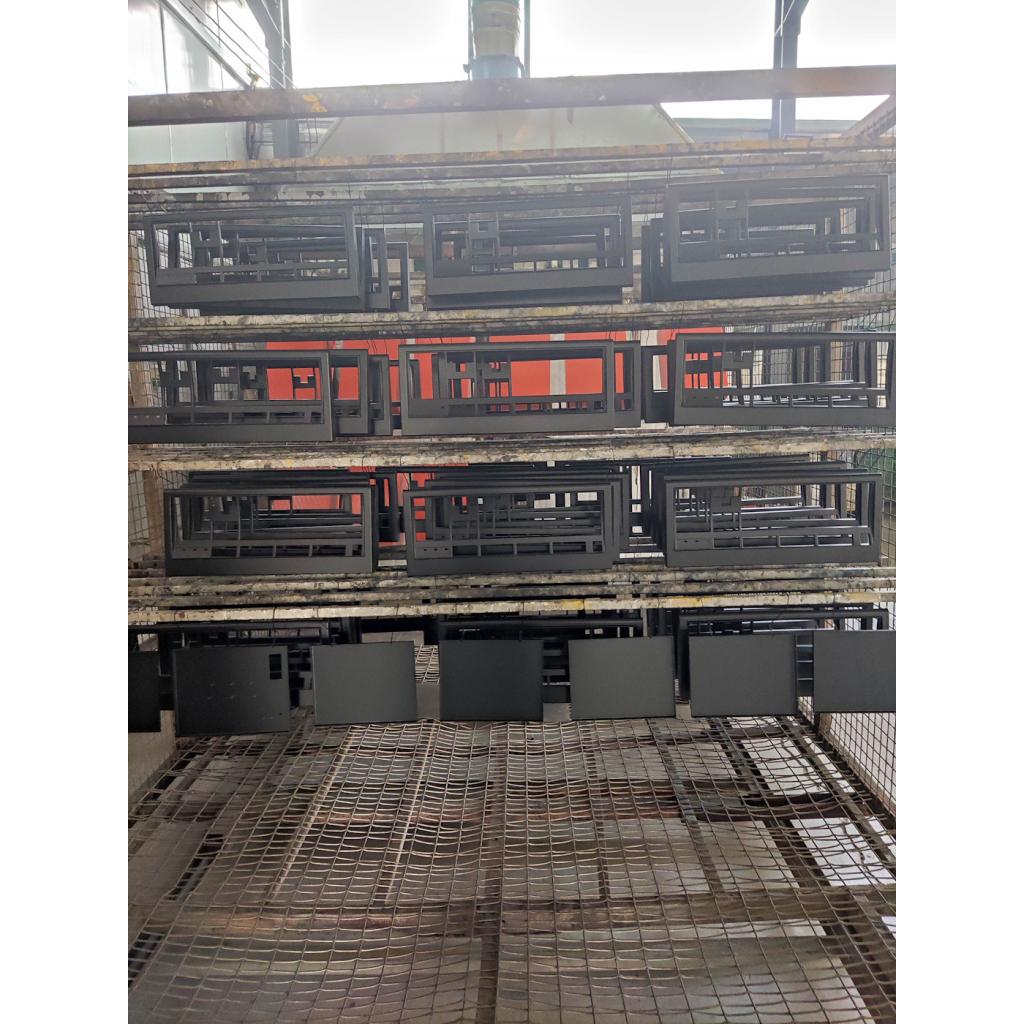

Here’s one photo from the approved sample – the gap in the back looks nice now.

There are a number of finishing operations required before the case can look nice and smooth for the powdercoating process. After die casting, the cases need to be die cast, drilled, and powdercoated, and then they can be assembled. I expect all to be on the same container shipment with the Round 2 beam spring boards.

All cases are powdercoated going forward, so they should look like the painted versions of the cases. The cases will have textured powdercoating, not like the smooth more modern powdercoating of the 2nd batch of ultra compact F62 and F77 cases (what has been shipping out in the past couple years), and not like the anodizing of the other compact cases (F104/FSSK/F15/F50/F Ergo). Here is a nice “group photo” of the F122 case samples being unboxed, from earlier this year, one in each of the available colors:

IBM Model M 122 spare parts (case, controller, cable, etc.)

Does anyone need an M122 early gen case (1989), a terminal controller for the 1390876, a terminal cable, the membrane contact sheets, the rubber mat, or backplate? I will be discarding them otherwise. Price is a few dollars above shipping for most stuff and $10 for the case (no cracks in the case but it is dirty). The case does not have the screws. Please email me if interested. The case has the one part risers in the back but otherwise looks like the F122 case on the outside.

Reminder on the following the manual for setting up your Brand New Model F and Beam Spring keyboards

As noted in the manual and in the printed booklet included with each keyboard, it is expected that some keys and springs will not function right away. Do not just install keys and start using your keyboard. Only follow the step-by-step instructions, videos, and troubleshooting guide available at ModelFKeyboards.com/manual where you can find valuable advice like “hold the keyboard vertically, space bar side up when installing keys.” Follow the manual to correctly remove and re-seat any key or spring as needed. Reinstalling one key many times will not solve most issues. Technical support requests cannot be accepted until after the user has reviewed the manual entirely and followed all setup and troubleshooting steps.

For anyone having issues with a key not being reliable, you may need to remove and replace the spring, not just reseat the key (see the video in the manual on the project web site for details). Even on new boards this happens: I might initially think there is something wrong with the hardware or firmware, but then I replace the spring with another one and the problem is completely gone. Recently I had an issue on a new board I was setting up, where two keys were transposed some of the time while typing fast. I double checked that both controller grounding screws were tight and then replaced both the keys’ springs with other springs and the problem was permanently fixed.

Many folks use their Model F boards as a reliable daily driver and do not have issues outside of having to reseat springs during the initial setup and periodically, but it is well worth keeping tweezers and spare parts handy to be able to use a Model F keyboard.

And of course if you have watched the full setup video and are still having difficulty, please head over to the Deskthority forum where there is a great community that can help with all sorts of mechanical keyboards.

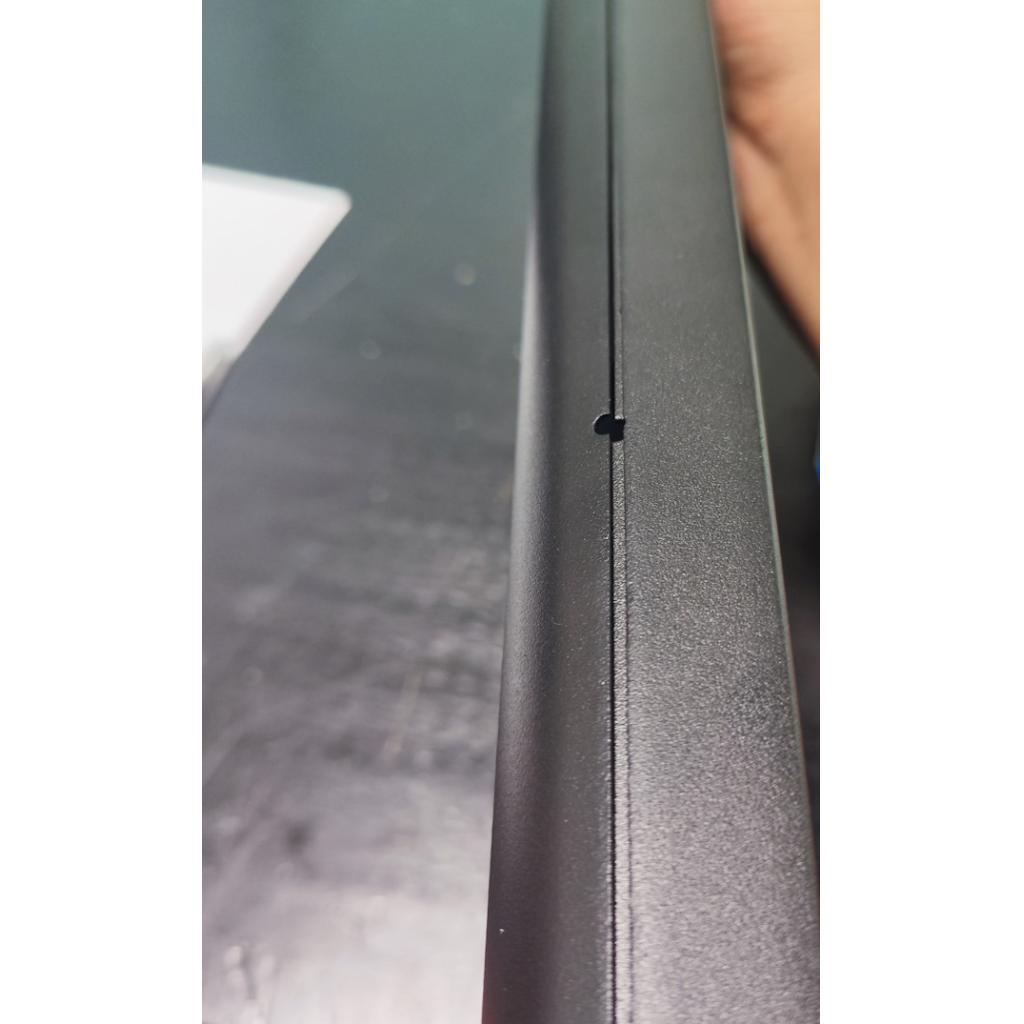

JIS New Production Key Set

After a number of requests, I have decided to proceed with making the JIS sets. Previously these sets, as well as the APL sets, were Unicomp sets. APL will remain Unicomp (unless someone wants to make the template as was done for the couple recent new layout submissions). I will be making the JIS front print option (not shown below in my draft). These sets were completed and the first 5 sets shipped to me by air, with the rest shipping in the next container shipment. I have a few of these left in case anyone wants one – just head over to the Full Key Set product page to order.

Keyboard feature in Linus Tech Tips video

Someone shared this link with me: Linus reviewing various computer setups, including a setup from Wendell that includes the Ultra Compact FSSK! About 7 1/2 minutes into the video:

Here is a video of a thoroughly modded new Model F keyboard – floss mod, stripped paint off of the die cast aluminum compact case, lubed Unicomp keys, etc.

Leyden Jar controller update

In addition to NathanA’s success with updating the various Model F keyboards to support Vial perfectly, Rico has made some exciting progress on the Leyden Jar Rev. 3 RP2040 controller, which is expected to be the default for the current round of the F122 and B122, and eventually for other boards when the ATMEGA-based stock is depleted. Rico’s controller also works perfectly in my testing. One big advantage of the board is increased memory with the RP2040. NathanA noted that the new Vial firmware for the ATMEGA controllers are getting closer and closer to filling up all of the available space.

We are now up to Rev3 and this one appears to be ready for mass production based on my recent testing. The controller has worked flawlessly in my testing, and it is quite stable. The F122 and B122 boards are expected to be powered by Rico’s new RP2040-based Leyden Jar controller which runs Vial, which is based on QMK. This controller has 2 additional columns (18 total instead of 16 columns, same row count of 8 rows) which allow for all of the extra keys of an F122. These controllers also can work on the other boards, though firmware is currently in progress for some of them, not yet done. For more details:

https://github.com/mymakercorner/Leyden_Jar

Even PS/2 support is planned!

Beam spring production process

After the sample order was assembled and tested back around the end of July, the updated beam barrels (part A and B) for Round 2 were approved for full production and I placed the order. These took a while to get right but I am glad everything is good now. Production is just about done: the modules are still in production, expected to finish around month end, and then they need to be assembled. The press-fit design is going to be saving a lot of assembly time compared to the older glued on washer design.

I also ordered the capacitive PCBs for all 8 beam spring variants and the F122, as well as the Leyden Jar version 3 controller for testing.

The 8 beam spring variants: B62 Split Shift and Regular Backspace, B62 Split Shift and Split Backspace, BSSK ANSI, BSSK ISO, B104 ANSI, B104 ISO, B122 ANSI, B122 ISO

The factory is also preparing the tooling to bend the aluminum cases. Then they will produce a full working sample keyboard of each design for verification, and then the case and inner assembly plates production can start. Then these need to be assembled and sent out on the container ship. The factory already completed a prototype of the new case and inner assembly design earlier this year and it has no issues, but to be safe I want to confirm that the new tooling makes things right for all the parts.

Metal badges

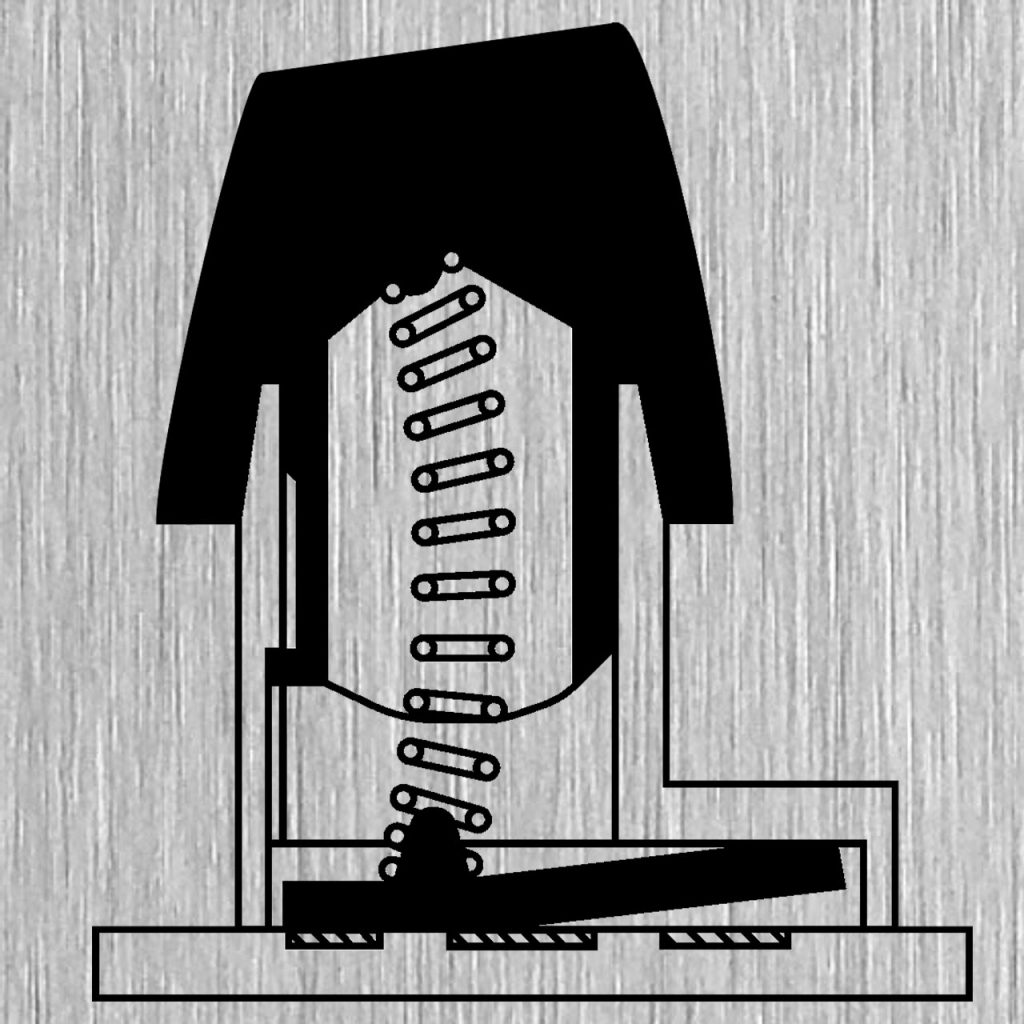

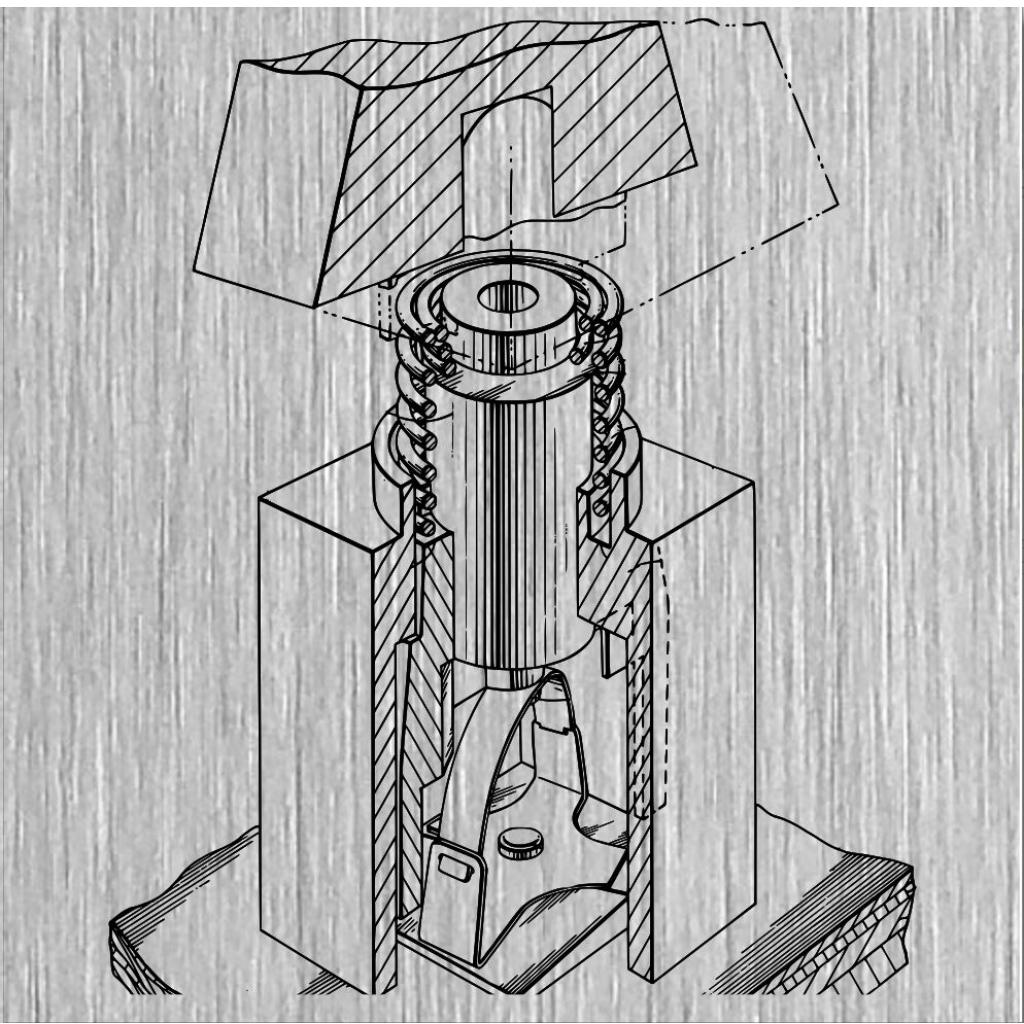

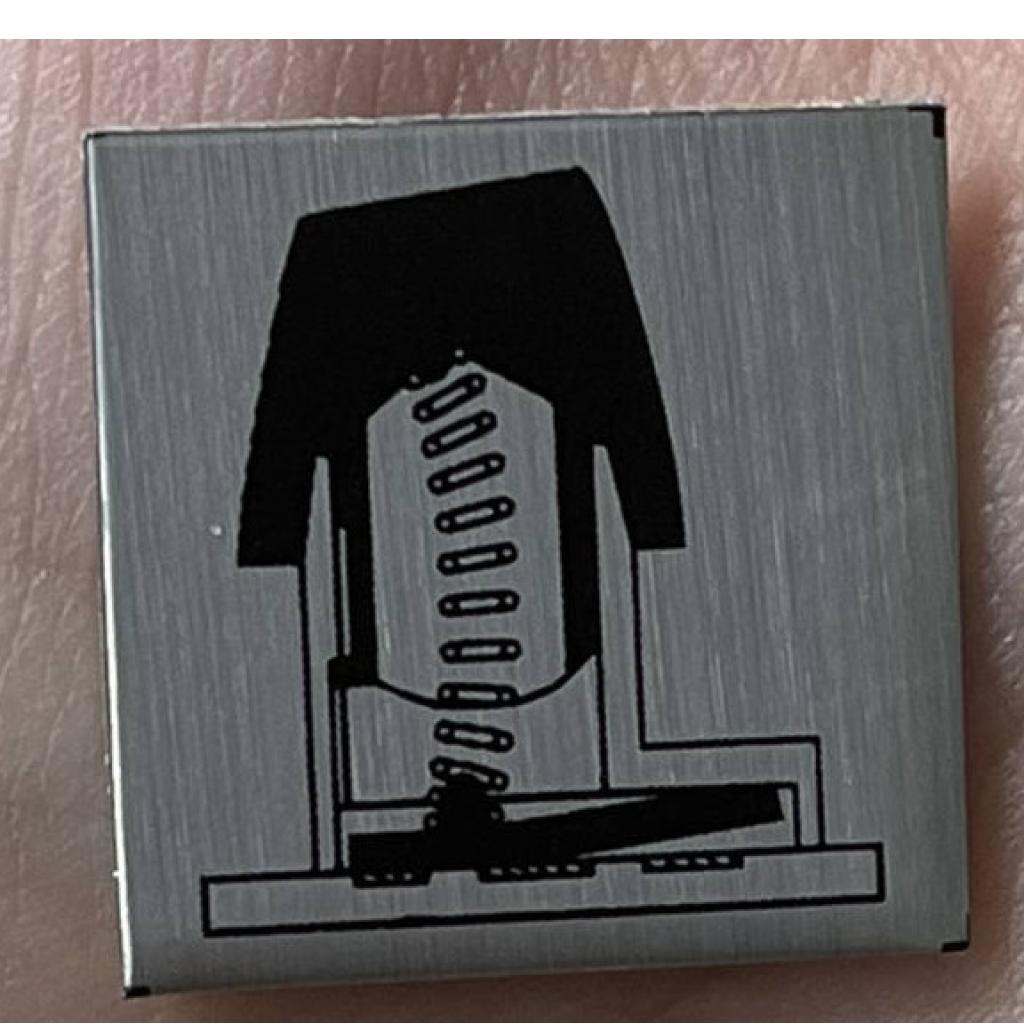

As noted a while back, new metal badges are being made for the project; you can now order them here. While all new Model F and Beam spring keyboards can have a badge affixed anywhere on the case, the F122 has a recessed spot for the badge, the same size as the smaller IBM badges used on the IBM F122, M122, Model M 1390131, and other boards. Any additional logos that should be produced? So far these two are in production.

There are 2 options – the Model F style and the Beam Spring style (renderings are shown above). If you would like for me to order additional styles, you will have to cover the tooling charges and commit to ordering 15 badges at a minimum. The MFL logo was not ordered due to lack of interest. The beam spring one has the bottom edge cropped not touching the edge on purpose, since the image would be far smaller if the entire beam spring drawing was visible on the badge. In the production art, the beam spring drawing extends much lower instead of being cropped as shown in the original rendering above.

Badges and LED overlays are the same size as the IBM originals and can fit most Model M or Model F keyboards, with exception for the IBM XT and AT boards that use a larger badge. These badges are 2cm x 2 cm. The F122 is the only new production board that has a recessed spot for the badge but you can stick the badges anywhere on any of the Brand New Model F or Brand New Beam Spring keyboard cases.

The factory also has the capability to make the black badges with the raised silver printing as well as the large AT/XT style, so let me know if you want to cover the tooling and order minimums to make any of those styles.

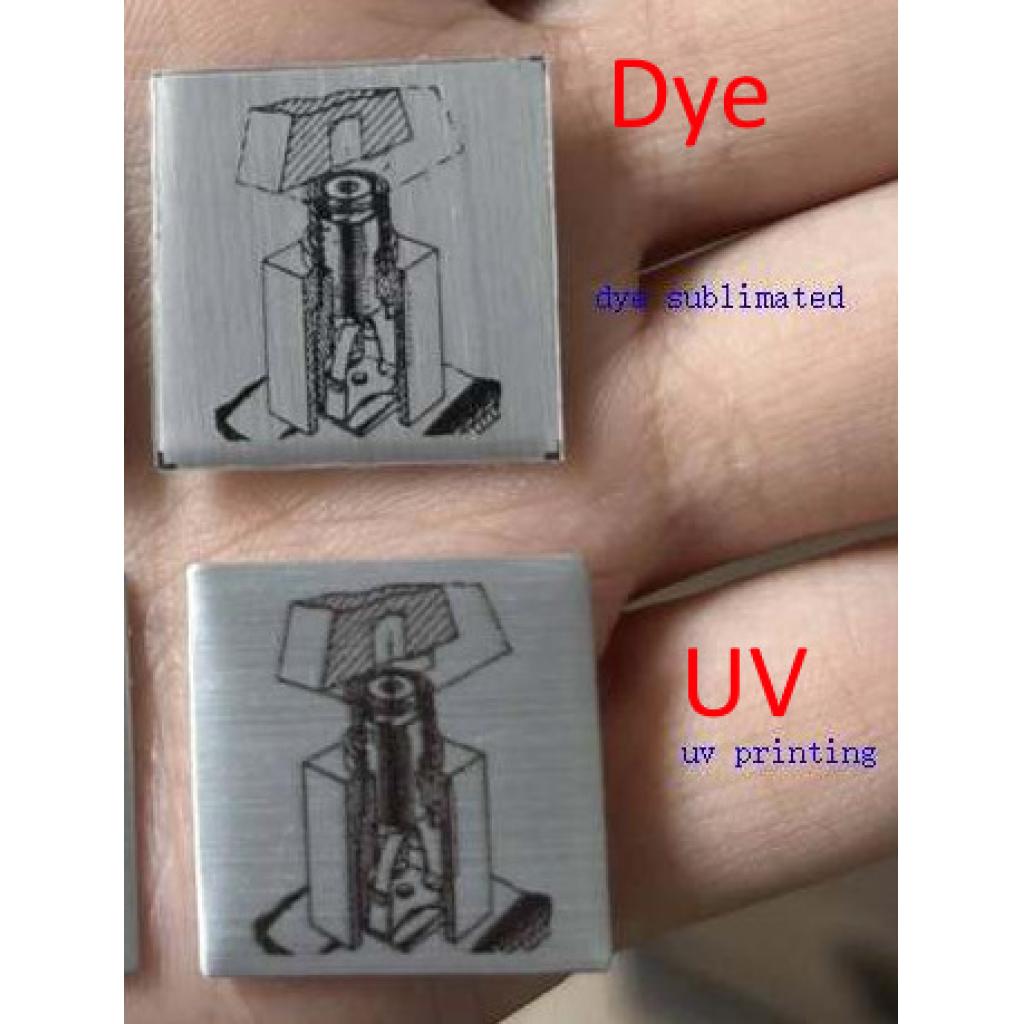

Last month I approved production of the dye sublimated badges. Almost no factories I asked even had the capability of dye sublimation to aluminum. They tried the UV printing option which was fine on its own but a bit fuzzier when compared directly to the dye sublimated option, as shown in the samples below (the samples have registration and other marks and rough edges that will not be on the production units).

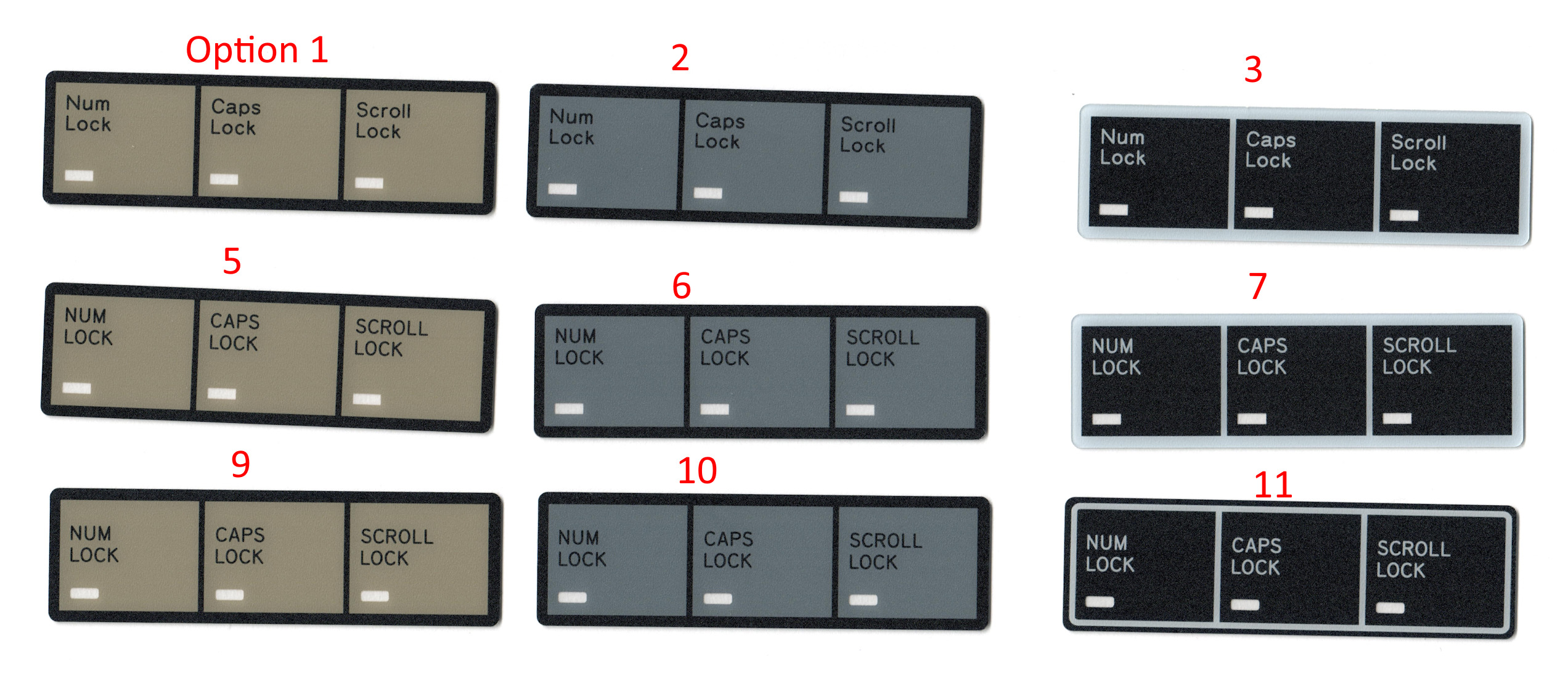

LED overlays

The remaining LED overlays arrived from the factory in August, and I mailed out all the orders waiting only on LED overlays and nothing else. I like the color of the beige overlay as it compares nicely with the originals. The gray overlays have a touch of blue in them, in my opinion, and the black overlays’ white areas also have a touch of blue in them. I would probably request less blue for a future order.

Model-F 5170 Converter for Raspberry Pi PICO RP2040

Here is an interesting project recently posted on reddit – an open source RP2040-based converter for Model F keyboards. Seems to be an alternative to ATMEGA based converters such as Soarer’s Converter that runs on an RP2040 instead of a Teensy / Pro Micro / etc. and connects to the original Model F controller instead of replacing it. It was made for the PC AT Model F but hopefully it will work with other boards either natively with a firmware update, or in the future.

https://github.com/PaulW/model-f-5170

https://github.com/PaulW/model-f-5170/blob/main/doc/custom_pcb.md

Custom 3d printed legs for the split ergonomic boards (F15 Split Ergonomic, F Split Ortho)

Already there is some development, even before these boards start shipping later this month! Copying one such project below:

“I set up a GitHub repo, that includes the following files:

-image of an assembled prototype leg that I think should work with the split ortho keyboard (the screw is an M6 size)

-image render of the 3d printed part

-an .stl file for 3d printing

-an .f3d file that can be modified

https://github.com/vanhornlab/Keebs-ModelF_Split_Ortho

Also on the GitHub is a description of the prototype leg. I intend once I have it to make two or three sizes so that the keyboard tents how I like. I have a few other ideas on legs like to make a bracket with a heat inset.

Anyway I hope it helps and I look forward to the keyboard.”

IBM Color matching

Some folks have been asking what are the exact colors of the IBM Beige and Industrial Gray.

I was able to use an i1 spectrophotometer to make the measurements, which have been sent to the factories making the cases. Of course IBM’s paint and plastic colors varied noticeably from case to case so your IBM case probably does not match these cases, so these values are provided to use at your own risk (probably better to take your case to the paint store where they can do an accurate match). Also the texture of paint as well as the uneven dirtiness and wear of the 6110344 case also adds some variance to measurement as my particular spectrophotometer is not geared to measuring textures. The beige on the screen looks quite different on my hardware calibrated monitor compared to viewing the keyboard itself, while the gray is similar.

Here are measurements of my F122 6110344 from 1984 and a brand new 1990s IBM Industrial Gray case. I took 10 samples from different areas of each case and averaged them.

Beige

LAB_L LAB_A LAB_B LAB_C LAB_H

77.028 -1.431 8.603 8.721 99.444

Industrial Gray

LAB_L LAB_A LAB_B LAB_C LAB_H

49.034 -0.727 7.576 7.612 95.464

Here is my old note on Higher force springs – these are still available

Is anyone interested in higher-force springs? I have a sample set of ~120 springs that were rejected as they required a little more force to process. The whole lot is available to one person so they have enough to fill a keyboard with them; please PM me if interested. Pricing will be based on best offer, with a minimum of $1 per spring. Flippers not included. Due to slight variations in the diameter of the flipper nubs I can’t guarantee this will work with original flippers (none of my springs are recommended to be installed on original flippers, as noted a while back). These ~120 springs are a slightly tighter fit than the production springs, so you have to press them a little more forcefully onto each nub. I would describe the sound as approximately the same as the production springs, maybe slightly quieter but still audible.

I also have 230 QC rejected springs without flippers (sound characteristics are off – too high pitch) available in batches of 80, 120, or you can take the whole lot. If you prefer a changing to a higher pitch spring this is the only batch available. Again, only recommended for new Model F flippers but will possibly work with originals. Pricing is the same $1 per spring.

Setting up a QMK configurator web site

While the project is moving over to the Vial-based firmware, thus avoiding the need for online configuration and making a new firmware every time you want to change the layout, Deskthority member snacksthecat managed to set up the QMK configurator and wrote up a nice guide.

“The only hitch that I’ve run into is that it seems to need to be rebooted every so often and the service light is always yellow (degraded). Maybe those things are related, but pandrew doesn’t seem to have the issue. Anyways…

Part 1 explains how to setup the configurator and add unofficial keyboards

https://www.keyboardjunk.com/p/setup-a-qmk-configurator-environment-with-docker-compose-part-1/

Part 2 explains how to setup SSL and use your own domain name

https://www.keyboardjunk.com/p/setup-a-qmk-configurator-environment-with-docker-compose-part-2/